Checking Out the very best Sikorsky Parts Distributors for Reliable Service and Support

Checking Out the very best Sikorsky Parts Distributors for Reliable Service and Support

Blog Article

The Relevance of Compatibility and Safety Attributes in Sikorsky Components Choice

In the world of aviation, the option of Sikorsky components demands a thorough concentrate on compatibility and safety attributes, as these elements are critical to both functional performance and the safeguarding of human life. Making sure that parts work reduces the likelihood of mechanical failures, while incorporated safety functions add significantly to system durability in damaging conditions. This discussion highlights the criticality of adhering to well established regulatory requirements and best techniques, yet it increases a critical question: what are the possible repercussions of disregarding these crucial factors to consider in the components option procedure?

Understanding Compatibility in Aviation Parts

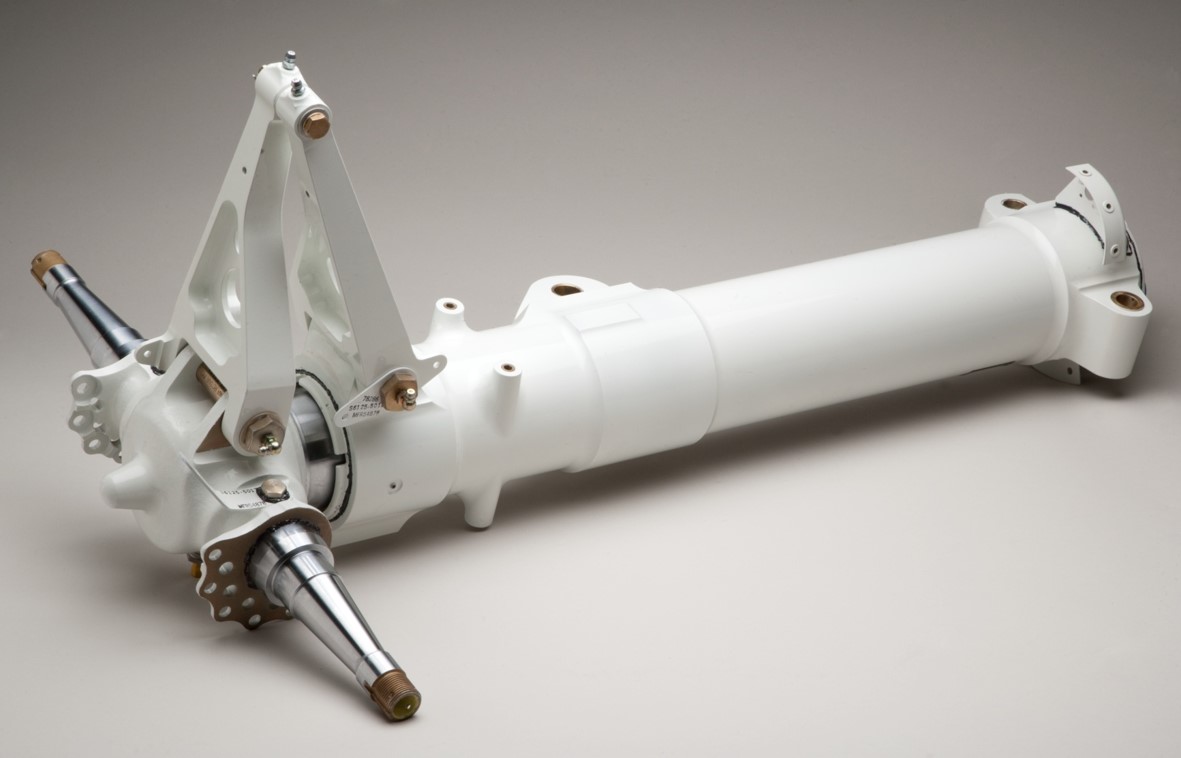

The complex systems within aircraft require that every part, from engines to avionics, job flawlessly with each other. When picking Sikorsky components, it is essential to examine whether they meet the recognized criteria and requirements for the certain airplane model.

Correct compatibility alleviates the risk of breakdowns and boosts the long life of the aircraft. Designers have to take into consideration different variables, such as load-bearing capacities, environmental problems, and compatibility with existing systems. A rotor blade designed for a specific helicopter model should be matched with the appropriate center and drive system to make certain optimal efficiency.

Failing to make certain compatibility can cause operational disruptions, raised maintenance expenses, and safety risks. sikorsky parts distributors. Subsequently, thorough examination processes, consisting of comprehensive paperwork and testing, are vital in the choice of air travel parts. By prioritizing compatibility, stakeholders can promote a culture of safety and security and integrity within the air travel industry, eventually contributing to successful missions and the well-being of guests and staff alike

Secret Security Includes to Take Into Consideration

Security attributes play an essential function in the option of Sikorsky parts, straight affecting the integrity and efficiency of airplane procedures. When assessing components, numerous key security attributes warrant attention to make certain optimal performance and risk mitigation.

Third, performance metrics such as load ability and fatigue resistance should be assessed to ensure that parts can deal with functional needs without endangering security. Fourth, the visibility of sophisticated monitoring systems can supply real-time information on part efficiency, allowing for aggressive upkeep and timely treatments.

Last but not least, conformity with air travel criteria and policies is non-negotiable. Guaranteeing that parts meet or exceed market security certifications guarantees adherence to ideal methods. By concentrating on these essential safety attributes, Sikorsky drivers can enhance the safety and security and reliability of their aircraft, inevitably adding to more secure air travel operations.

Threats of Incompatible Components

Utilizing inappropriate components in Sikorsky airplane can result in substantial operational threats that jeopardize both safety and efficiency. The integration of parts that do not meet stringent compatibility standards can lead to mechanical failings, decreased integrity, and potentially tragic mishaps (sikorsky parts distributors). Such failings often arise from dissimilar specifications, consisting of inaccurate dimensions, products, or design tolerances that might not align with the aircraft's initial design specifications

In addition, using incompatible components can disrupt important systems, such as avionics or propulsion, leading to a loss of control or reduced ability to move during trip. This not only threatens the staff and passengers but likewise postures risks to ground workers and spectators. The ramifications of using incorrect parts prolong beyond instant security worries; they can additionally lead to pricey repairs, prolonged downtime, and enhanced obligation for operators.

Eventually, making sure that all parts are suitable and follow the supplier's specs is crucial for keeping the honesty of Sikorsky airplane. A positive technique to components choice is important to mitigate these risks, guaranteeing optimal efficiency and guarding the lives of all those aboard.

Regulative Specifications and Compliance

Making certain conformity with regulative standards is extremely important when picking parts for Sikorsky airplane. Regulatory bodies such as the Federal Air Travel Administration (FAA) and the European Union Aeronautics Security Agency (EASA) develop strict standards that regulate the layout, manufacturing, and upkeep of air travel parts. Adherence to these requirements is crucial to guaranteeing the safety and dependability of aircraft procedures.

Conformity with regulative criteria not only safeguards the lives of guests and crew however likewise protects the stability of the aircraft itself. Parts have to go through strenuous testing and qualification processes to validate they meet efficiency and safety and security criteria. This consists of evaluating materials, style specifications, and making methods.

In addition, preserving documents that shows conformity is vital for accountability and traceability. In the occasion of examinations or audits, having extensive documents ensures that all components satisfy the needed governing needs.

Picking parts that are accredited and compliant with well established governing standards helps reduce dangers connected with non-compliance, such as legal consequences and functional downtimes. Inevitably, focusing on governing conformity partially option enhances More hints Sikorsky's dedication to quality in aeronautics safety and security and efficiency.

Ideal Practices for Components Option

Reliable parts choice is an important procedure that straight influences the performance and dependability of Sikorsky airplane. To make sure optimum capability, it is essential to abide by numerous finest practices in the selection process. Extensive study on each part's requirements, consisting of product homes and compatibility with existing systems, need to be carried out. This reduces the risk of malfunctions as a result of incompatibility.

Following, focus on sourcing parts from reputable makers that conform with sector criteria and have a proven performance history of dependability. This step is important to maintaining safety and security and making sure regulatory compliance. In addition, applying a robust confirmation procedure, including examinations and screening, can help verify that picked components fulfill all operational demands.

In addition, keep complete documents of all parts and procedures to promote traceability and responsibility. This technique not only help in compliance yet also supports more efficient maintenance and possible troubleshooting in the future.

Finally, participate in continuous training and growth for workers associated with components choice to remain informed regarding the most current advancements and ideal techniques in the industry (sikorsky parts distributors). By adhering to these best methods, Sikorsky airplane operators can improve safety, dependability, and general efficiency

Final Thought

In recap, the relevance of compatibility and safety attributes in Sikorsky components choice is paramount for ensuring functional effectiveness and airplane security. Proper compatibility analysis minimizes the risks of mechanical failings, while important security Clicking Here attributes improve system reliability.

Report this page